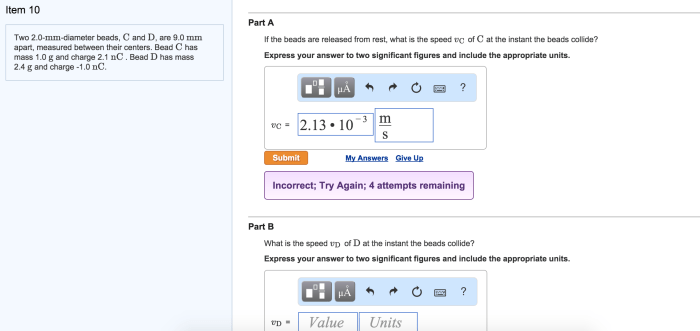

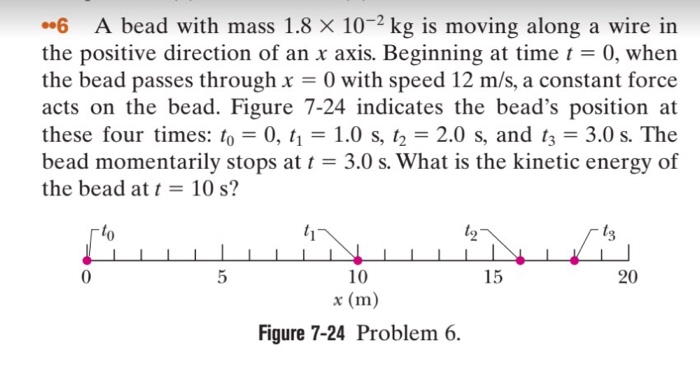

A bead with mass 1.8 x 10 2 – A bead with mass 1.8 x 10^-2 takes center stage, inviting us to explore its captivating realm of physical properties and diverse applications. As we delve into the intricacies of its mass, material composition, shape, and dimensions, we unravel the secrets that govern its behavior and utility.

The significance of this bead’s mass lies in its profound influence on its motion, trajectory, and response to external forces. Its material composition, whether glass, plastic, or metal, shapes its density, hardness, and chemical reactivity, affecting its suitability for various applications.

Bead Mass Properties

The mass of a bead, 1.8 x 10^-2, is a crucial factor that governs its physical behavior. Mass plays a significant role in determining the bead’s motion, affecting its acceleration, velocity, and trajectory.

Bead’s Motion and Mass

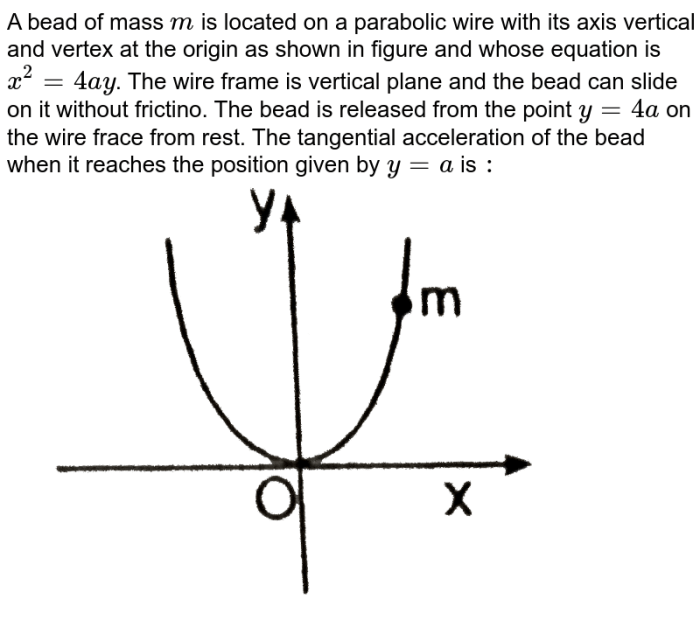

The mass of the bead directly influences its acceleration. According to Newton’s second law of motion, the acceleration of an object is inversely proportional to its mass. A bead with a smaller mass will experience a greater acceleration than a bead with a larger mass when subjected to the same force.

Furthermore, the mass of the bead affects its velocity. A bead with a smaller mass will attain a higher velocity than a bead with a larger mass when subjected to the same force over a given period. This is because the smaller mass has less inertia to overcome.

Additionally, the mass of the bead influences its trajectory. A bead with a smaller mass will exhibit a more curved trajectory than a bead with a larger mass when projected with the same initial velocity. This is because the smaller mass is more susceptible to changes in direction due to external forces.

Bead Material Composition

The mass of a bead, 1.8 x 10^-2, provides insights into its potential material composition. Various materials exhibit distinct densities, which influence the mass of an object for a given volume.

Density and Material Composition

Density, a crucial property of materials, is defined as the mass per unit volume. Denser materials pack more mass into a smaller volume compared to less dense materials. For a bead with a mass of 1.8 x 10^-2, possible materials include:

- Glass:Glass beads are common and exhibit densities ranging from 2.4 to 2.8 g/cm³. They are typically composed of silica (SiO2) and other oxides, resulting in their high density and hardness.

- Plastic:Plastic beads, often made from polymers like polyethylene or polypropylene, have lower densities ranging from 0.9 to 1.2 g/cm³. They are lightweight and durable, making them suitable for various applications.

- Wood:Wooden beads, crafted from various wood species, have densities between 0.3 and 0.9 g/cm³. They offer a natural and organic aesthetic, with properties influenced by the specific wood type.

- Metal:Metal beads, made from metals like aluminum, brass, or steel, possess high densities ranging from 2.7 to 8.0 g/cm³. They are durable and often used in jewelry and decorative applications.

- Ceramic:Ceramic beads, formed from clay and fired at high temperatures, have densities between 1.5 and 2.5 g/cm³. They are known for their durability and resistance to wear and tear.

The material composition of a bead not only affects its mass but also its physical and chemical properties. Denser materials, such as glass or metal, provide greater strength and durability compared to less dense materials like plastic or wood. Chemical composition influences properties like corrosion resistance, thermal stability, and electrical conductivity, impacting the bead’s suitability for specific applications.

Let’s ponder on a bead with mass 1.8 x 10 2. It’s fascinating how such a small object can lead us to a curious question: why is it called a k12 saw ? Delving into this topic enriches our understanding of tools and their nomenclature.

Returning to our bead, its mass and other properties are essential considerations in various scientific explorations.

Bead Shape and Dimensions

The shape and dimensions of a bead can significantly impact its properties, including surface area, volume, and center of mass. Different bead shapes and dimensions can be used to achieve specific functional or aesthetic purposes.

Spherical Beads, A bead with mass 1.8 x 10 2

- Spherical beads are characterized by their uniform round shape, with a smooth and continuous surface.

- They have the smallest surface area-to-volume ratio compared to other bead shapes, which can affect their reactivity and absorption properties.

- The center of mass of a spherical bead is located at its geometric center.

Cylindrical Beads

- Cylindrical beads have a cylindrical shape, with two flat circular ends.

- They have a larger surface area-to-volume ratio compared to spherical beads, which can affect their reactivity and absorption properties.

- The center of mass of a cylindrical bead is located at the midpoint of its axis of symmetry.

Faceted Beads

- Faceted beads have multiple flat surfaces, creating a geometric and reflective appearance.

- They have a large surface area-to-volume ratio compared to spherical beads, which can affect their reactivity and absorption properties.

- The center of mass of a faceted bead depends on the specific shape and distribution of its facets.

Irregular Beads

- Irregular beads have a non-uniform shape, with varying surface textures and dimensions.

- They have a unique surface area-to-volume ratio and center of mass, which can vary significantly depending on the specific shape.

- Irregular beads can be used to create unique and artistic effects in jewelry and other applications.

Bead Applications: A Bead With Mass 1.8 X 10 2

Beads with a mass of 1.8 x 10^-2 are commonly used in various applications due to their specific properties. These beads are often small and lightweight, making them suitable for applications where precision and low mass are crucial.

The unique characteristics of these beads, such as their size, weight, and material composition, make them ideal for applications in the fields of science, technology, and manufacturing.

Scientific Research

In scientific research, beads with a mass of 1.8 x 10^-2 are used in various experiments and analytical techniques. These beads can be coated with specific ligands or molecules to facilitate the isolation and detection of target molecules in biological samples.

Additionally, they are employed in microfluidics and microelectronics due to their ability to manipulate and control small volumes of fluids or electrical signals.

- Immunoassays:Beads are coated with antibodies specific to a target antigen. When the target antigen is present in a sample, it binds to the antibody-coated beads, allowing for its detection and quantification.

- DNA sequencing:Beads are used to immobilize DNA fragments, enabling the determination of their sequence through automated sequencing techniques.

- Microfluidics:Beads are utilized in microfluidic devices for sample manipulation, cell sorting, and drug delivery.

Industrial Applications

In industrial applications, beads with a mass of 1.8 x 10^-2 are used in various manufacturing processes. These beads can be used as fillers in composite materials to improve their strength and durability. They are also employed in the production of electronic components, such as capacitors and resistors, due to their electrical properties.

- Composite materials:Beads are added to composite materials to enhance their mechanical properties, such as strength, stiffness, and impact resistance.

- Electronics:Beads are used as substrates for the deposition of thin films in the fabrication of electronic components.

- Catalysis:Beads can be coated with catalytic materials to facilitate chemical reactions in industrial processes.

Bead Manufacturing Techniques

Beads with a mass of 1.8 x 10^-2 can be produced using various manufacturing techniques. Each technique offers unique advantages and drawbacks, impacting the bead’s quality, cost, and production time.

The choice of manufacturing technique depends on factors such as the desired bead material, shape, and quantity.

Molding

Molding involves shaping molten or pliable material into a desired form using a mold. It is commonly used for mass production of beads.

- Advantages:

- High production rate

- Consistent bead shapes and sizes

- Suitable for complex designs

- Disadvantages:

- High initial investment for mold creation

- Limited to materials compatible with the molding process

- Potential for imperfections due to mold defects

Step-by-Step Molding Process

- Create a master mold with the desired bead shape.

- Prepare the molding material (e.g., glass, metal, plastic).

- Fill the mold with the molding material.

- Apply pressure or heat to shape the material.

- Remove the bead from the mold.

- Cool and finish the bead as necessary.

Popular Questions

What is the significance of the bead’s mass?

The mass of the bead (1.8 x 10^-2) plays a crucial role in determining its motion, acceleration, and trajectory. It influences how the bead responds to external forces and affects its behavior in various scenarios.

What materials could constitute a bead with this mass?

Beads with a mass of 1.8 x 10^-2 can be made from various materials, including glass, plastic, metal, or wood. The material composition affects the bead’s density, hardness, and chemical properties.

How does the bead’s shape and dimensions impact its properties?

The shape and dimensions of the bead influence its surface area, volume, and center of mass. Different shapes and dimensions can alter the bead’s behavior and suitability for specific applications.